History embossed on our premium wooden cases

About the unique collaboration between La Maison du Pastel and Krepel

One of the best things about our work is that we get to cooperate with all kinds of special companies from all over Europe. For example, we are proud of the unique collaboration we recently started with the French company La Maison du Pastel. Owners and artisans Isabelle Roché and Margaret Zayer produce high quality and handmade pastels for artists. They needed premium packaging for gift sets or bespoke palettes, and this is where we came in. We talk to Isabelle and Margaret about their company and the cooperation with Krepel.

About La Maison du Pastel

Meet the oldest pastel manufacturer in the world! The Story of La Maison du Pastel starts at the beginning of the 18th century, a time when working with pastels was very much in fashion. Artists such as Quentin de la Tour, Chardin and Rosalba Carriera contributed to its notoriety, and the pastels produced in Paris were renown throughout Europe. Chemist Henri Roché took over a French art materials manufacturer in 1879 and revolutionized it, creating the Roché pastels that became renown worldwide for their specific qualities. Today, more than 1900 pastel nuances are available to artists.

La Maison du Pastel is a very interesting company with an amazing history! Why did you decide to ask Krepel to produce the wooden packaging for some of your products?

Margaret: “Our history is indeed quite extensive, full of highs and lows, and can sometimes be traced by its packaging! We are currently on an upswing, and therefore the demand for the house-finished boxes we have been making and selling for years began to outstrip our capacity. Following a request for a potentially significant order, we went on the hunt for potential suppliers who would be reliable and meticulous in their work. We decided to contact Krepel after seeing the variety and quality of finishes they offered for a number of other notable companies.”

What types of pastels come in the wooden packaging made by Krepel?

Isabelle: “We offer these boxes as an upgrade option to customers offering gifts or creating bespoke palettes, as well as for the setting of certain half-stick sets.”

How did you come up with the design of the box?

Margaret: "These boxes were directly inspired by models we sold from the late 19th and early 20th centuries that were either branded or embossed with our signature dragon.”

How do you describe your collaboration with Krepel?

Isabelle: “The experience of working with Krepel is everything we could have hoped for, and more. They have been consummate professionals at every level, from prompt and reliable communication to the careful packaging of our boxes. We appreciated their interest in our project, attentiveness towards our needs, and the initiatives they took to make suggestions and recommendations when it came to approving prototypes.” Margaret: “We would absolutely recommend Krepel to other companies!”

Lacquer of perfect quality without wasting a drop

Krepel invests in new sustainable and efficient spraying line

The paint department at our production site in Poland has a new employee. And not just someone! Our new, durable and super-efficient spraying robot paints a large proportion of our cases now. This allows us to deliver even faster and the lacquering quality is much more stable. Curious to see how the lacquering of our products looks like now? Then click on the video below!

“We're always looking for ways to produce in a more sustainable manner. But we’re also searching for solutions to make our production process even more efficient," says Sławomir Ćwikła, Managing Director of our production site in Poland. "At a trade fair, we came across this spraying line that can paint 20-30 cases at once. When we saw what it can do, we knew: we have to invest in this. The lacquering line we acquired was made especially for us. Completely tailored to our products and requirements."

Quality

The new spraying line has a lot of advantages. It works faster than human hands ever could and can also be used 24 hours a day. In addition, the paint is applied very evenly to all sides of the box. As a result, the quality is perfect and always the same.

Sustainable

In terms of sustainability our new ‘bot' is also a good match for Krepel. Sławomir: "The lacquer is sprayed very efficiently and, as a result, we save considerably on the amount of lacquer needed. Moreover, the machine itself ensures that the lacquer that does remain from a particular can is mixed with a new can. This means that literally nothing is wasted.”

Three types of lacquer

Our new advanced spraying line has three different options when it comes to finishing. For example, you can choose to have your Krepel case sprayed with thin and breathable nitro lacquer. Or instead go for the strong and pliable polyurethane lacquer. Looking for a sustainable alternative? Then go for our water-based lacquer.

In addition to lacquer, Krepel has many other finishing options for our products. All these options can be found here.

Which look are you going for?

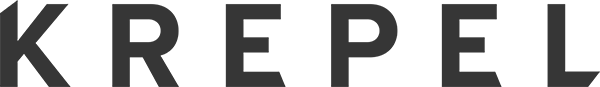

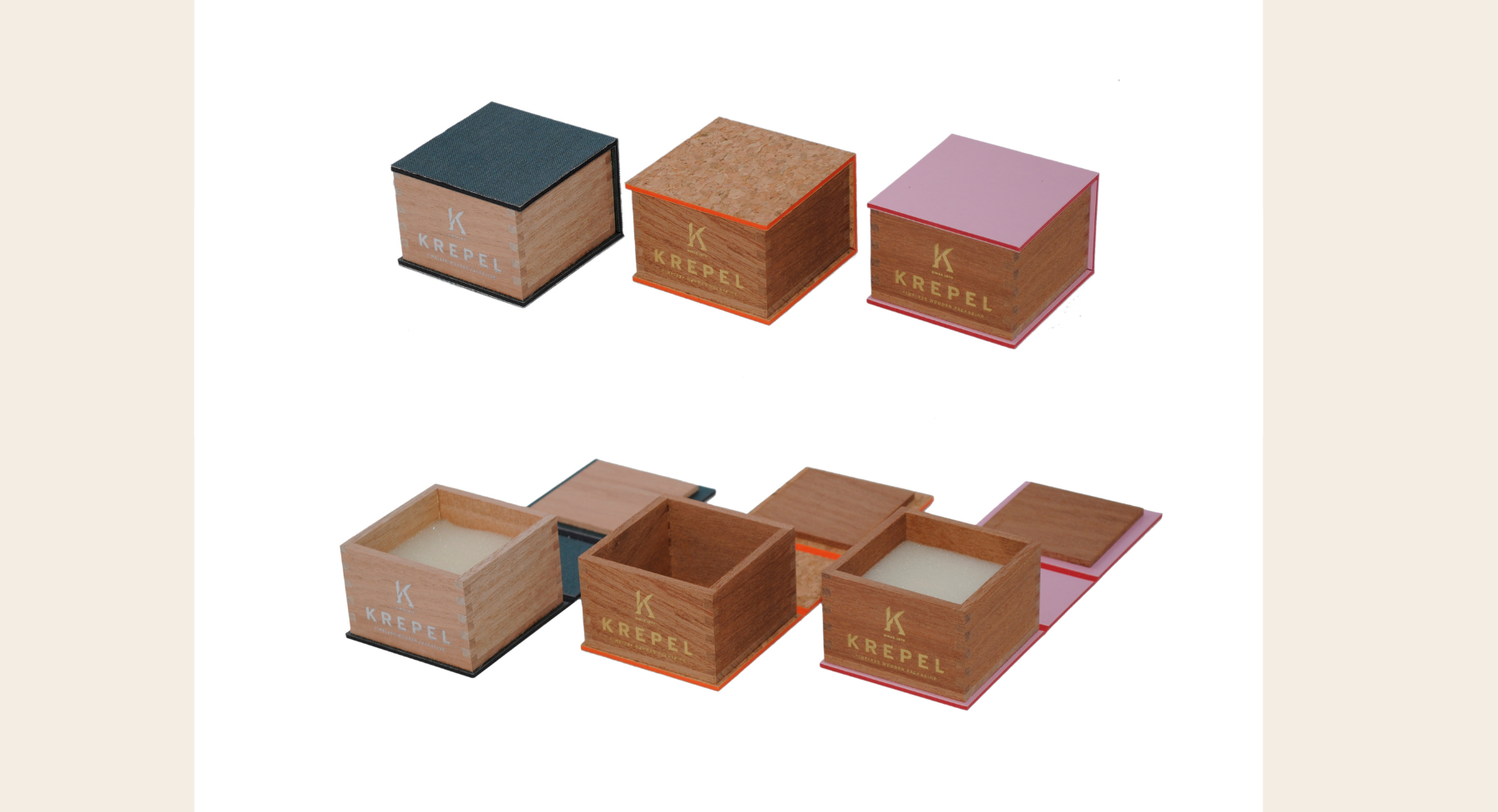

Krepel adds fully personalised cardboard cover to its range

Linen, leatherette, cork, suede or your company colours: give your wooden packaging a unique style! You can now combine our wooden boxes with a cardboard cover. This cover can be fully personalised in accordance with your preferences. With a cool leather look, for example, or with the suede look of flock foil. Or perhaps you prefer the natural feel of linen? Sales manager Agnieszka Miter-Pawlowska from our production site in Poland tells us more about the new possibilities at Krepel.

“A fully personalised cardboard cover is new in our market, so we’re very excited we can now offer this option! It gives our customers the opportunity to highlight their products in a completely new way,” says Agnieszka enthusiastically. “In addition to all the options we already offer to make your wooden packaging your own, many more options have been added thanks to the new personalised cover. Our range has really expanded now.”

Custom made

Krepel chose to add the cardboard cover to the range because personalising packaging is becoming increasingly popular. Agnieszka: “Customisation is extremely important in our sector and we would of course like to offer even more options. Feel free to ask for a quote if you’re curious about how your packaging would look with a cardboard cover.”

“I personally think the combination of wood and the natural feeling that linen evokes is incredibly beautiful. I think a linen cover is my favourite. The same applies to a cover with a cork structure, that also makes me feel as if I’m walking in nature.”

Experience the depth and class of 3D

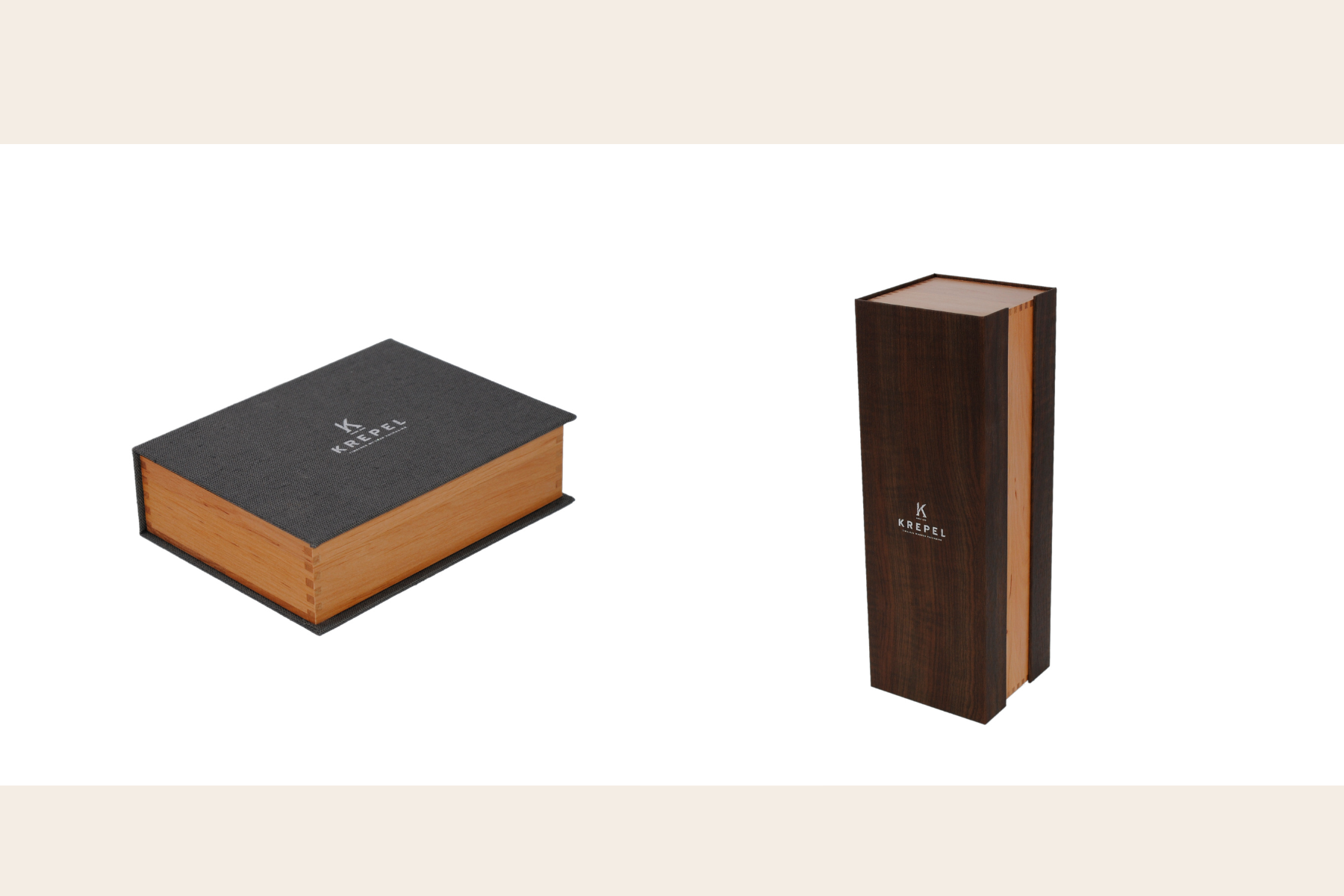

Krepel launches unique printing possibilities thanks to new UV printing technology

Imagine: the letters of your company name seem to pop out of the wooden packaging, printed images come to life and your logo has more depth than ever before. We will soon be able to realise this thanks to the investment in a special new UV printer. This model prints faster, with even better quality and can print with a unique 3D effect. With this, we are taking a big step forward in our industry and we are a leader in Europe in the field of UV printing technology on luxury wooden packaging. All of these new features will be available this autumn.

“The options that the new UV printer offers in terms of quality, finish and personalization are enormous,” says Sławomir Ćwikła, Managing Director of our production site in Poland. “Images, text and logos are now printed in even more detail, colour and brilliance on the different types of wood we use. But the most special thing about this printer is the 3D effect you can create with it. This allows you to make certain details from images, letters or logos stand out.”

How it works

The 3D effect that will soon be possible thanks to the new UV printer gives our packaging a completely new dimension. But how does this technology work? Sławomir: “A standard UV printer contains four colours of ink: black, blue, yellow and red. In addition, white ink is used as a base layer. This is also the case with our new printer, but it also contains transparent white lacquer that allows us to print an extra layer in certain places. This creates the 3D structure. This is not only possible on wood, but also on other materials such as glass, leather or paper.”

“Here in Poland we’re already preparing to start using the new printer soon. Of course, we’ll make full use of all the new possibilities! We’re looking forward to really getting to work for our customers this autumn,” says Sławomir.

Of course, we’ll keep you informed in our newsletter and on the website when the new UV printing technology is available.

Want to sign up for our quarterly newsletter? Send your contact details to: info@krepel.com

Artisanal incense cones in premium wooden packaging

About the unique collaboration between Waldweihrauch and Krepel

One of the best things about our work is that we get to collaborate with all kinds of special companies from all over Europe. For example, we are proud of the unique collaboration we recently started with Austrian company Waldweihrauch. Florian and Angelika Gruber produce artisan incense cones with homegrown herbs. The special-edition cones needed premium packaging and this is where we came in. We talk to Florian about his company and the collaboration with Krepel.

How did you come up with the idea for Waldweihrauch?

“We started Waldweihrauch in January 2020. At that time, we had already been producing incense cones for several years. We made our first incense cones on our small organic farm. The company was founded because we had to separate farming and the production of incense cones. This is because in Austria, farms mainly produce ‘Urprodukte’ which are unprocessed goods like the dried herbs we grow on our farm.”

What makes Waldweihrauch's incense cones unique?

“Our artisanal incense cones do not contain synthetic essential oils and we don’t use artificial additives such as saltpetre. We mainly use herbs from our farm and resin from our own black pines. All cones are made according to local Austrian recipes. We also make incense cones that contain special types of incense: this is our ‘Premier Cru’ line. Cones with six kinds of boswellia incense, for example. And third, we went through old books to recreate scents from past times. From this, we created cones with six different scents from nineteenth-century France.”

Why did you decide to ask Krepel to produce the wooden packaging for part of your range?

“When we were just starting out, we packed three of our cones together with four matches in a cardboard matchbox. This way of packaging not only provides protection, but you can also use the packaging to light the cones. So two birds with one stone. But when we heard from some customers that they found the matchboxes a little too simple for our premium cones, we decided to start using wooden boxes for our special-edition cones. I started looking for the boxes that appealed to me and came across cigar boxes from De Olifant. I contacted them and learned that Krepel made the boxes. After that, contact with Krepel was quickly established.”

How did you decide on the design of the boxes?

“I used the dimensions of De Olifant’s cigar box, because it was very suitable for shipping seven cones. We developed the larger box, which fits six different types of cones, ourselves.”

How do you describe your collaboration with Krepel?

“We experience it as very good and productive. Antoon Pelgrim is always helpful and has good suggestions on how best to implement our ideas. I would definitely recommend Krepel to other companies that need premium wood packaging!”

Van Tienen’s fiftieth anniversary sealed with stylish tea chest for anniversary tea 1973

It all started in 1973, when Tien van Tienen from Brabant started selling vending machines for tea and coffee. His company grew rapidly and Van Tienen is now one of the largest suppliers of coffee machines, cups, sugar, milk, soft drinks, cleaning supplies and other products used in corporate canteens and kitchens. This year, the family business celebrates its 50th anniversary, which is why the new 1973 tea concept was developed: 100% organic fair trade tea of high quality. It was up to us to design and produce a stylish tea chest for them. We spoke to account manager Bart van Tienen about this special collaboration.

‘What I like so much about the collaboration with Krepel is that the lines of communication are so short. Two years ago, when we wanted to have a tea chest made for our own Tientime tea brand, I came across Antoon Pelgrim van Krepel through the grapevine. He came by and everything just fell into place instantly: beautiful products, a good price and personal contact. So there was no need to look any further’, says Bart. ‘So when we needed a chest for our newest product, anniversary tea 1973, it made sense for us to work with Krepel again’.

Family business

Bart is part of the third generation within the family business and grew up in the business. ‘The nice thing about working with your family is that you know exactly what you have in common. That has both advantages and disadvantages, but above all it’s a lot of fun. For me, the business has always been part of my life’, he explains. ‘Granddad started working for Simon Lévelt in 1963 and after ten years wanted to start his own business selling vending machines for coffee and tea. He agreed with Hans Lévelt that he could bring all his own customers with him, but on the condition that he would always continue to sell Simon Lévelt with the vending machines. Now, fifty years later, this collaboration is still very strong and Simon Lévelt is our largest coffee and tea supplier. In 2000, granddad passed on the baton to the second generation and our range continued to expand. We are now a total supplier for everything you need in corporate canteens and kitchens. From vending machines to biscuits and cleaning supplies. We also have a number of private labels of tea and coffee, of which anniversary tea 1973 is the newest.’

Of course, Van Tienen will not let the fiftieth anniversary pass unnoticed. Among other things, an anniversary magazine was printed, a festive kick-off of the anniversary year was celebrated and a number of open days are scheduled. Bart: ‘Our new private label 1973 appeared at the end of 2022, which coincided very nicely with our anniversary year. We noticed that many customers were ready for something new instead of the standard Pickwick tea and we want to respond to that with this tea line. It is one hundred percent organic fair trade tea in unbleached paper filter bags. We try to keep the product as sustainable as possible. With 1973 we’re aiming for the SME segment and so far, the tea has been very well received’.

Simple and stylish

To be able to present the new tea in a stylish way in your company, Van Tienen called in Krepel again for the design and production of a tea chest. ‘Everything went smoothly with Antoon, as usual. We were looking for a serene and sleek chest that would fit into all kinds of businesses. Simple, yet stylish. And of course our bags had to fit exactly’. The result was an 8-compartment chest with the 1973 logo on it and inside a brief text about how the company was founded in 1973. ‘We supplied our logo and the text for the inside and the rest of the design was handled very well by Krepel. Antoon personally brought the first sample. It was very nice to be able to see and talk to each other again’.

The 1973 anniversary tea chest is now available via the Van Tienen webshop.

From holiday worker to international sales manager

Antoon Pelgrim celebrates 40th anniversary at Krepel

In 1982, Antoon joined Krepel as a holiday worker. A year later, he became a permanent employee, in a position that, as someone from Twente, he initially had some doubts about. ‘“Dorpels liemer”, they said’, says Antoon. In other words, someone who glues thresholds in the door department. He soon made the switch to the production of boxes and started as a salesman in the office a year later. Antoon: ‘In fact, I still do, both in the office and in the field and all over the world. But if someone asks me what I do, I always answer with “I sell boxes”. No fancy titles, just simply what I do. I have a wonderful profession. And if you’ve been working in the same place for 40 years, you simply have a good employer where you can talk about everything.’ We talk to Antoon about his anniversary at Krepel.

‘Peeling wood was the most beautiful thing to see’, Antoon begins his story while standing next to the imposing machine that was used to peel wood years ago. He explains how tree trunks were clamped and then several metres of wood peels were produced in different thicknesses for the production of wooden boxes. Next to the machine are some photos that emphasise the craft. ‘It’s still a craft’, says Antoon. ‘We deliver custom work. It is a wonderful process when a customer wants to put a product on the market and wants to have it packaged nicely. We work closely with our clients and designers. We create unique wooden packaging that complements products so that a correct and appealing overall picture is created.

Wooden packaging top three

When we ask Antoon about his packaging top three, he doesn’t have to think long. ‘The Elephant series!’ he says resolutely. ‘They’re available in big and small versions and have been around for about 40 years. Nothing has ever changed in terms of appearance, the boxes are an example to me of how beautiful simplicity can be.’ Also in Antoon’s top three: the imposing limited edition boxes for the Rembrandt collection from Royal Talens and the stylish and detailed packaging for a piece of jewellery from Aurum Brothers.

Working under three generations of Krepel

With 40 years of employment, Antoon has worked under no fewer than three generations of Krepel. ‘They all ran the company in their own way, but all with the same passion’, says Antoon. ‘When I started, Jan-Richard Krepel (senior) was leading the family business. An old-school manager. Jan-Richard Krepel who succeeded him was really into cigar boxes. He was extremely handy. He sometimes stood by me when I was making boxes, which of course would go wrong at that moment. Who knows that’s why he thought “let’s put him in the office”’, says Antoon with a laugh. Jan-Richard moved the production location to Poland and Bernhard - the current generation - also implemented changes within the family business. ‘Krepel continues to innovate. We are investing in new techniques and we can offer customers more and more. That makes the profession wonderful and our services relevant’, Antoon concludes.

Text and portrait photography: Mariëlle Schiphorst-Dolman | Vormbeeldig

A sustainable production location

Renovations spring 2022

Several renovations are scheduled for our production location in Poland this year. For example, the current incinerator will be replaced after 20 years and a silo will be installed. Krepel has been working completely gas-free for years now and these renovations enable us to work even more environmentally friendly and we meet the most stringent standards.

We have been using wood waste as heating fuel for years. “In the past, it was only possible to burn solid wood. The new incinerator, which will be installed in the spring of 2022, can also burn other wood-based materials, such as plywood or MDF. This means we can really use all our residual materials for heating purposes”, says Sławomir Ćwikła (Managing Director at Krepel in Poland).

More power and more environmentally friendly

Apart from the fact that there is even less residual waste, we provide the paint department with process heat and we can make the process even more environmentally friendly. The modern incinerator with a capacity of 600KW is not only stronger compared to the old model, but also much more efficient. “Our storage and production areas have been expanded by a few thousand square metres in recent years. We currently need to heat approximately 4,200m2, including our offices. The new system takes care of the entire heating”, Sławomir explains.

By applying a higher combustion temperature, a longer process and a modern filtration system, it is possible to reduce the emission of harmful substances by more than 90%. Thanks to an automatic emission measurement in the incinerator, we don’t exceed the applicable EU standards either. In fact, we meet the most stringent standards.

Continued automation

“Whereas until now employees filled, stored and transported bags with ash and sawdust by hand to the incinerator, this will soon be fully automated. It makes the process much more efficient. The new silo has a capacity of 300m3. This ensures waste materials can be stored in a single safe place. In addition, a fully automatic supply of wood fuel (ash and sawdust) to the incinerator is made possible thanks to the installation of an ash transport system that runs directly from the sawdust extractor to the silo. The installation of a wood chipper also improves the process”, says Sławomir.

Packaging for 23-year-old genever

The great collaboration with Hooghoudt

It all started in 1888, in a small cellar at Oosterstraat, a street in the very centre of Groningen. Currently the fifth generation is working at Hooghoudt, which can still proudly call itself a family business. The collaboration between Krepel and Hooghoudt sprang from a special project: developing the packaging for a 23-year-old genever. This genever is the result of barrels that at the time were filled by Hero Jan Hooghoudt (third generation).

At Hooghoudt they offer something for everyone, which means that genever has different target groups. Genever can take on the flavour of a gin, or you can let it mature which makes it more like a whiskey. “We can dress our genevers with botanicals, which has a strong impact on flavour,” Michiel Brandsma, product manager at Hooghoudt explains. “For example, hops, iris root, liquorice and orange peel have been added to the unique 23-year-old genever that is now on the market. We continue to enrich people’s taste palettes.”

Export to US and Chinese markets

In addition to a barrel that is bottled for the Dutch market, barrels are reserved for export to America and China. “For some time now, we’ve been working together with a number of other genever brands to put genever back on the map in America,” Michiel says. “In the US, genever is gradually growing in popularity. You can tell that the whole gin hype over there is a bit past it. Bartenders, for example, are looking for something unique again. The broad taste palette of genever offers a solution here, also for applications in cocktails. There is a need for special products for the Chinese market, as the market for these is huge. The Sweet Spiced Genever, which includes candy, cinnamon and vanilla, is our regular genever for the Chinese market. This is a sultry genever that makes for a perfect serve with ginger ale and lime and tastes like a fresh summer cocktail. With the 23-year-old genever, we are also bringing something completely different to the market in China.”

Unique packaging for a unique product

A unique product like the 23-year-old genever deserves unique packaging. Packaging that accentuates quality and authenticity. The apparently basic wooden packaging fits in well with the philosophy of the Hooghoudt brand and creates an attractive unit with the bottle thanks to the choice of materials and elements that have been applied. Oak has been used, which is the same type of wood from which the genever barrels are made. “In total there will be five generations of packaging, each symbolising the Hooghoudt generations. The bottles that come in the packaging are all unique. For example, the wax stamps are never identical and each label bears the relevant barrel and bottle number. The icons we use in the wax stamps also appear on the wooden packaging and can be traced back to the ingredients of the genever and the history of the family brand,” Michiel explains.

The packaging is open, so the bottle is central in its overall presentation. The engraved icons, for example, show the Groningen stamp, the year of creation, a still, juniper berries, a royal crown and a ‘hoogholtje’. The latter is a high wooden bridge typical for the north of the Netherlands and from which the Hooghoudt family name originates. The icons seem to be placed randomly, but their positioning has been thought through in detail.

Collaboration with a stylish result

“We had an idea for the packaging and an image of what it more or less should look like. Our question was specific, but there were also some vital details that still had to be thought out and we very much enjoyed working with Krepel in doing just that. And with a stylish result!”, Michiel says. “For example, the bottle had to be easily removable, yet remain secured in the packaging when held at an angle,” explains Antoon Pelgrim. He is a sales manager at Krepel and worked closely with Michiel. “The solution turned out to be a subtle wooden insert that keeps the shape of the packaging intact. This insert stays in place thanks to a magnet of exactly the right strength. We’ve placed foam on the inside to protect the wax cap of the bottle against any possible damage. Everything revolves around the presentation of the bottle, but the bottle must also be pristine once out of the packaging. In addition, we’ve looked at how we can develop the most appealing packaging for each market whilst still working with an identical basis. For example, the stamps for the Chinese market have not been moulded, but printed with gold foil.”

Smart ingenuity

Unique tea box for Quooker

Sjoerd Vroonland (Studio Vroonland) is a designer who loves wood just as much as we do. He allows functions of existing products to merge into stylish new designs. This also applies to the tea chest he designed for Quooker and that he produced in collaboration with Krepel.

Combining functions

The tea chest is perfect in its simplicity. And that simplicity is exactly what makes this design so incredibly powerful. All elements flow seamlessly into each other, forming a stylish set in the process. The tea chest can be easily slid open thanks to a subtle opening at the back. On top, a ring has been moulded from the wood, which immediately gives a different perspective in terms of use of the box, as this can be used to put the tea bag on. By combining functions, the tea chest can also be used as a serving tray.

Simplicity is not easy

The way in which Sjoerd so aptly applies the power of simplicity in his design fits in perfectly with Quooker products. “Quooker supplies the best tap for boiling water currently available in the world. It looks like any other tap, but the smart part is hidden inside. I wanted to use that design feature in the tea chest. I couldn’t just make a tea chest that opens and closes and that’s it. It had to be something that takes you by surprise, like a discovery within stylish simplicity. But once you start talking about simplicity, it’s actually getting more complicated. The ring on top looks simple, but you can only do these things together with parties who can perform this to perfection. And the simpler it gets, the more perfect it has to be,” Sjoerd explains.

Ultimate collaboration

After talking to multiple parties, Sjoerd ultimately came to Krepel for the production of the tea chest and that turned out to be a good match: “The collaboration is magic. I dare call this the ultimate collaboration. The tea chest has something of me, the ingenuity of Quooker and the rock-solid quality of Krepel. The first samples were very good straight away. We only had to put the icing on the cake. You can produce a single tea chest to perfection, but if you produce it in large quantities, the quality has to be constant and Krepel lives up to that.”

Close cooperation

“It was a joy having Sjoerd so closely involved in the production process,” Antoon (Sales Manager at Krepel) says. “As a designer, he has the exact end result in mind. And besides clear sketches, it does also involve the necessary instinct. Creating a sample and fine-tuning it until the result is perfect are all part of this process. And the best thing is that this collaboration has led to a follow-up assignment. We are originally a producer of wooden cigar boxes. Sjoerd is working on a new type of cigar packaging, in which Krepel can make a difference as well. It’s wonderful to see how new ideas arise and take shape when you work so closely together.”

Sjoerd doesn’t hide his enthusiasm either. “My father smokes cigars as do I sometimes. So I know the standard cigar boxes and cigar cases inside out. This collaboration with Krepel and their rich history have inspired me to develop cigar packaging that is going to be quite different from the standard. It’ll be an altogether new product.”

How product and packaging become one

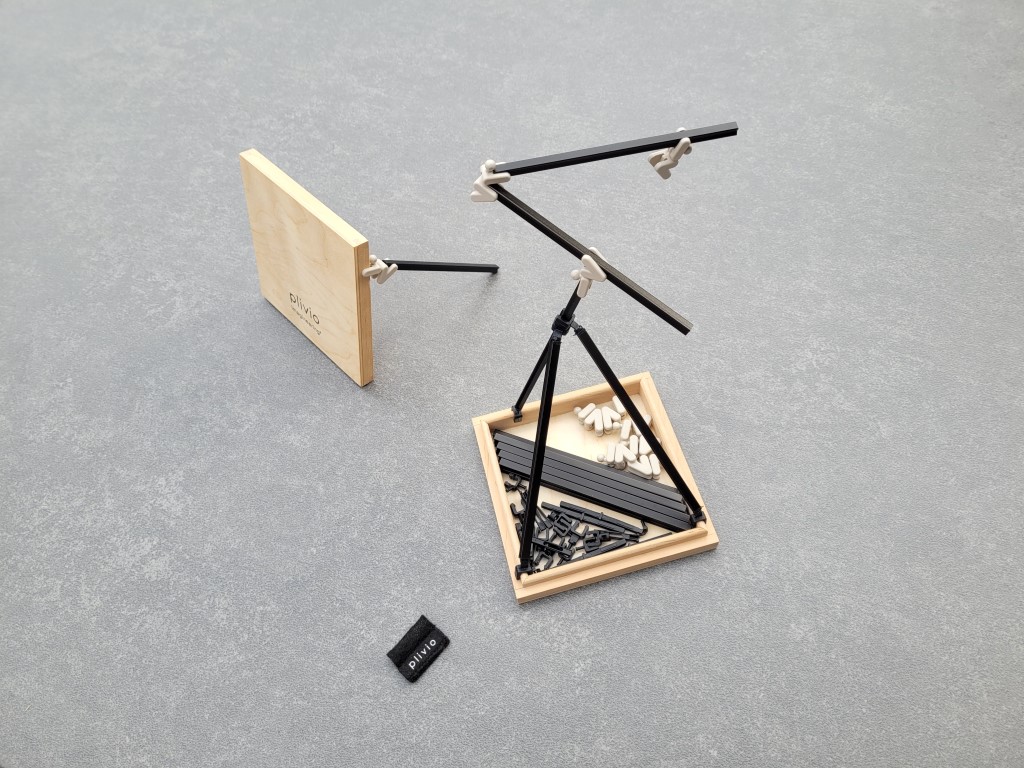

Simplistic and stylish: packaging for Plivio

The wooden packaging should always perfectly match the product we are packing, that is one of our starting principles. But for Plivio, we went a step further. The wooden packaging became part of the product.

Every detail is right

“For Plivio, we made a sleek and very minimalist box. It is a simple design, but in combination with the product it creates a beautiful look in which every detail is just right,” explains Antoon Pelgrim, sales manager at Krepel. Plivio produces 'imagineering sets.' Unique boxes containing 3D construction sets with aluminium tubes, twistable figures and handy, modular connections. Krepel has made boxes for two different versions: the entry-level model 'the box' and 'the master box' for advanced users.

Packaging for playful design

Plivio is a so-called playful design that challenges adults to rediscover their innate playfulness. The design is minimalistic and sleek but offers a host of options for making all kinds of constructions and connections. “The development of the 3D construction sets has taken several years. It was not easy to find the right suppliers who could offer the required quality within the correct tolerances. In addition, we were constantly optimising and improving the constructions and the required components,” says Hein Wille, founder of Plivio. By perfecting and listening to feedback from the market, they developed a smaller version alongside 'the master box', the entry-level model 'the box'.

The wooden box is part of a creative construction

Plivio is a product in which spatial insight, imagination and creativity come together. “We call it 'imagineering', one word that says it all,” explains Hein Wille. “We are also indirectly saying that the possibilities are endless, so we wanted to make it possible to involve the packaging in the constructions. In order to build solid and stylish constructions, the manufacturing of the packaging required precise craftsmanship from Krepel. The tolerances necessary to achieve the right clamping between clamping parts and the edge of 'the box' involved tenths of millimetres.”

Part of the development process

The small figures that are part of the 'imagineering' sets can also be clicked precisely onto the edge of 'the box'. For the smaller version, no partition walls were used, which further emphasises the simplicity of the design. “We find it important that the contents of the boxes always stay in place, which is why we now use tubes that can only fit into the box in one particular way. Having Krepel as part of the development process, was a real must. Thanks to the excellent collaboration, we were able to create a box where everything is right, down to the last detail. The figures and some parts click flawlessly onto the edge and the appearance of the box embodies what Plivio is all about. The boxes may seem minimalistic, but they are beautiful in their simplicity,” says Hein Wille. “Besides that, working together with Antoon was very pleasant. He contributed ideas and was very clear about what is possible and what is not. I had no previous experience with wooden boxes, so his support and advice was incredibly important to me in the development phase."

The Plivio imagineering sets will be available in such places as design shops, museum shops and the better bookshops.